WALL-MAN MAN LIFT

WALL-MAN MAN LIFT

The Wall-Man personal pneumatic man lift is designed to fit spray booths (for painting) and preparation booths for many different segments, where explosive gases and fumes are present (ATEX-environments):

- Aerospace (planes/certain parts of planes)

- Buses

- Coaches

- Commercial Vehicles

- Railway

- Military

- Engineering (various objects to be painted, ie transformators, windmill blades etc)

Energy

The Wall-Man man lift only needs to be connected to compressed air, with a recommended pressure of 7 bars. Using air as energy also keeps the operational costs low. Air is commonly accessible many places inside a spray booth or preparation booth.

Quality and durability

The Wall-Man man lift system is well known for its quality and durability. The Wall-Man work platform has been exported and sold to over 40 countries worldwide for over 30 years. The pneumatic Wall-Man access platform is designed to last for 25 years (8 hours per day, 250 days per year), justifying the investment and ensuring an efficient booth for years to come.

How you control the Wall-Man

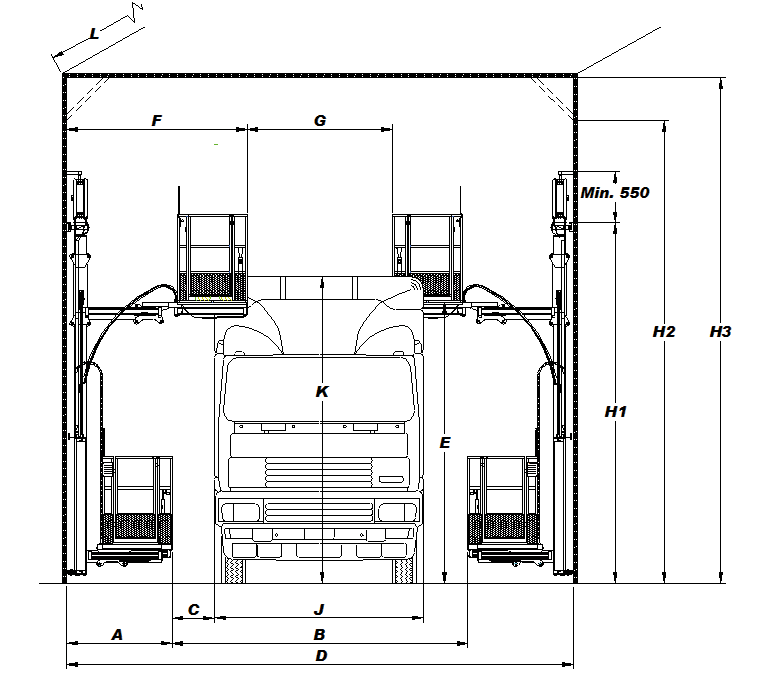

The Wall-Man man lift is controlled by the operator from a control console located in the front of the platform, this allows the worker to face forward and observe the area as they move the lift. The lift travels on a guide rail system with the upper rail fixed to the wall and the lower wheels are running on the wall of the booth.

X-axis

The X-axis travel (left and right movement of the lift) allows the lift to travel back and forth along the length of the booth on the upper rail system.

Z-axis

The Z-axis travel (up and down movement of the platform) provides the ability to elevate the operator platform from a lowered position to a maximum height of 4,525 meters, giving the operator approx. a working height of 6,4 meters.

Y-axis

The Y-axis travel (in and out motion of the operator platform) provides the ability to move the operator platform from a retracted position from the wall to a fully extended position of 2,585 meters (from the booth wall to the front of the operator platform).

The fixed Wall-Man’s features and benefits to the customer:

- Better safety for the operator when performing work at height

- Entirely pneumatically operated

- A work platform with low life time costs

- Increased performance and efficiency in the paint booth- less overspray

- No contact with the floor – no need to move hoses on the floor

- An extra outlet for air tool is provided inside the basket

- On demand – a dust extraction kit can be installed

- Made to order / fit the customers requirements (spray and/or preparation booth and object)

- Built in safety features to ensure the highest level of safety

- Three dimensional movement (including telescopic movement)

- CE, CSA and UL certified (executed by TÜV and UL)

- ATEX compliant

Optional feature

The Wall-Man pneumatic man lift is also certified for 200 kgs and a wider basket (1200mm) – to allow two operators in the same basket. This requires minimum 8 bars on the system in order for the Wall-Man to operate as meant to. This feature needs to be requested upon request for proposal.

For sales and/or prices for our man lifter equipment you are encouraged to contact us at: info@reglo.no or call us at +47 33 43 02 80.

Download the checklist for quotation here.

Video of the Wall-Man:

Design: Mounted on the wall – no contact with floor, ergonomic operation

Construction: Welded steel

Finish: RAL 5015

Net weight: 320 kg

Energy: Entirely pneumatically operated

Functions: Three dimensional movement; up/down, in/out, left/right

Characteristics: Easy to install, minimum of maintenance.

Models: From 500 to 1300 mm telescopic extension –

lifting height (floor of cage) up to 4,5 m

Payload: 150 kg (one person + equipment)

Controls: Inside cage: Up/down, in/out, left/right

At ground level: Up/down

Brakes: Brake system in rail for steady positioning.

Optional: brakes on lower support wheels.

Air supply: 6-8 bar, min. 350 ltr/minute supplied via hoses on self-retracting

reels or via energy chain. A compressed air outlet for air tools is provided in the cage.

Imposed loads:

Upper rail: Vertical load approx. 460 kg

Horizontal load approx. 120 kg

Lower support wheels: Vertical load 0 kg

Horizontal load approx. 120 kg

(Model 1000 – std. lifting height)

Approvals: CE, CAS and UL certified. ATEX compliant.

Up/down:

- Safety flow restrictors in case of air loss

- Chain straightener

- Safety factor 11 on lifting chains

- Safety chain on air supply

- Chain slack protection

Sideways:

- Brake system for steady parking

- Guide rollers to centre the travel in top rail

- Rubber stoppers in rail

- Loss of air pressure allows manual movement

In/out:

- Pressurized cylinders for steady positioning

- Loss of air pressure allows manual movement

Miscellaneous:

- Non slip floor in cage

- Signal horn

- Chain protection panels

- Hook in cage for safety harness

- Self closing hinges

- Self closing latches

- Emergency lowering

| WALL-MAN standard models |

Distance from wall min/max (A/F) |

Cage size width/depth |

Lifting height std./max |

Axis |

| 500 | 885/1385 | 900/570 | 3275/4525 | 3D |

| 600 | 935/1535 | 900/620 | 3275/4525 | 3D |

| 700 | 985/1685 | 900/670 | 3275/4525 | 3D |

| 800 | 1035/1835 | 900/720 | 3275/4525 | 3D |

| 900 | 1085/1985 | 900/770 | 3275/4525 | 3D |

| 1000 | 1135/2135 | 900/820 | 3275/4525 | 3D |

| 1100 | 1185/2285 | 900/820 | 3275/4525 | 3D |

| 1200 | 1235/2435 | 900/820 | 3275/4525 | 3D |

| 1300 | 1285/2585 | 900/820 | 3275/4525 | 3D |