What is a fume extraction system?

Fume extraction consists of various mechanical solutions that remove toxic and carcinogenic fumes, gases, and dust. A fume extraction system is necessary in processes such as welding, hot work and metalworking, all of which releases gases and particles. Some fume extraction systems are also useful in other industrial processes such as grinding, vacuuming, polishing etc.

Why is welding fume extraction necessary?

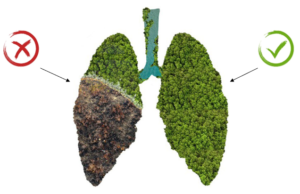

It has now been established that pollution from all types of welding is carcinogenic. That is why welding fume extraction is necessary. The IARC (International Agency for Research on Cancer) has recently classified welding fumes and UV-radiation from welding in risk group 1. Group 1 contains carcinogens – a term for substances that have sufficient evidence of carcinogenicity in humans – examples are Asbestos, Plutonium, Chromium-VI, tobacco smoke – and now also welding fumes.

Welding fume extraction prevents toxic and carcinogenic particles from polluting the worker’s breathing zone. It also prevents deterioration of general air quality for all other personnel who might be in the same vicinity. For the best possible protection, it is important to eliminate the pollution as close to the source as possible.

Important reasons for using welding fume extraction

The most important reasons for using welding fume extraction are:

– To meet new and stricter requirements from the authorities regarding working conditions around all types of welding, and hot work and metalworking that releases gases and particles

– To reduce absence due to health issues

– To reduce wear, cleaning and maintenance needs on other machines and equipment

– To increase the productivity, product quality and well-being at the workplace

Available types of welding extraction solutions

Two types of welding fume extraction solutions are available: High vacuum and low vacuum.

High vacuum extraction

Does it satisfy the new and stricter norms and regulations?

High vacuum welding extraction is the solution that best satisfies the new and stricter norms and regulations from the authorities. It also ensures that the contaminants are eliminated as close to the source as possible. This is done by means of either a welding gun with integrated extraction, or via movable extraction nozzles that are placed in the immediate vicinity to where the work is being performed.

If you weld over a distance or in different places, a welding gun with integrated extraction is recommended. However, if you weld relatively statically, an external high vacuum suction nozzle can be the most effective solution.

https://reglo.no/effective-removal-of-welding-smoke-how/

Can high vacuum systems be used for other purposes?

High vacuum systems can be used for other purposes such as extraction of dust and particles from grinding, polishing, dry and wet vacuuming etc.

Will high vacuum extraction solution reduce my energy costs?

Due to the low air volume that is required, a high vacuum extraction solution will reduce your energy costs, i.e. the costs of heating or cooling your facilities, compared with other extraction solutions. In fact, high vacuum extraction removes as little as one tenth of the amount of heated / cooled air compared to low vacuum.

Is high vacuum extraction effective on robotic welding machines?

The extraction nozzle can be mounted directly on to the welding gun, ensuring that the nozzle always is in the immediate vicinity of the source of contamination. You do not have to encapsulate the welding robot to catch the welding fumes. This in turn contributes to improved air quality as well as less wear, less cleaning, and less demand for maintenance of the welding robot and other equipment nearby i.e. high vacuum extraction is very effective on robotic welding machines.

Low vacuum extraction

Can I place low vacuum extraction nozzle close enough?

Low vacuum extraction solutions consist of large ducts and extraction funnels that are manually positioned above the welding site. Due to the size, they often get in the way of the worker’s field of vision. Because of this, low vacuum extraction funnels can sometimes be difficult to place close enough. As a result of this they are often placed too far away from the source to be effective enough, and this in turn causes contamination of the worker’s breathing zone.

Does it satisfy new and stricter norms and regulations?

Because fumes spread in a conical shape, the result is that less carcinogenic welding fume is captured compared to using a high vacuum system. The worker’s breathing zone and the general air quality in the room gets polluted. Spreading of pollution is precisely what you do not want/are allowed to do to satisfy new and stricter norms and regulations from the authorities.

Does it increase the energy costs?

Low vacuum extraction solutions require a larger amount of air compared to high vacuum. Up to ten times more air is removed from the room – per workstation. The replacement of all this heated or cooled air will increase the energy costs in your premises.

What about mobile solutions?

There are also mobile solutions available for extraction, both high- and low vacuum systems. However, please keep in mind it is not allowed to recycle air from hot work back into the room when this can be avoided using permanent solutions.

What type of extraction solution is best suited?

To determine what type of extraction solution that is best suited for your company you need to look at your needs and surroundings. But in general, it can be said that solutions that eliminate the pollution as close to the source as possible is recommended. This gives the best possible result and satisfies the new requirements from the authorities.

Over 40 years of world-wide experience

Reglo offers both EFFEX high vacuum extraction solutions, as well as low vacuum extraction solutions. We have over 40 years of world-wide experience with solving pollution challenges when it comes to welding fumes and other dust/particulates from other metal working processes. Our product line contains everything from small portable solutions for one operator up to larger systems for hundreds of operators. We have also delivered multiple extraction solutions for robot welding machines – including several systems for some of the world’s largest car manufacturers.

Feel free to contact us for no obligation inspection to uncover your needs and requirements. After this, we will have the opportunity to offer you the solution that best meets your and your company’s needs.